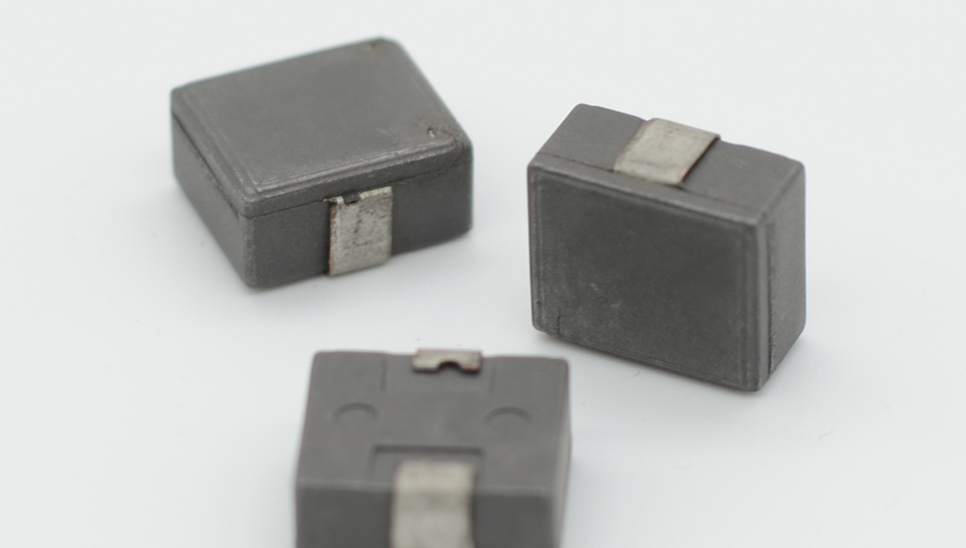

Bonded NdFeB magnets are generally used in the motor industry. This material is a permanent magnet material, which is generally not easy to demagnetize, but there are also demagnetization problems. And the injection molding NdFeB magnet occupies a very important position in the motor manufacturing industry and has the characteristics of strong magnetism. However, we should also pay attention to anti-corrosion when using. Generally speaking, the corrosion resistance of injection molded NdFeB is much better than that of sintered NdFeB due to the protection of plastic matrix. However, electroplating or coating treatment should also be carried out to improve its anti-corrosion performance under high temperature and high humidity conditions. Today, let's briefly analyze the problems in this regard.

I. Cause analysis of demagnetization of injection molded bonded neodymium iron boron magnets

1. Demagnetization caused by the material itself

NdFeB magnet has the advantages of high remanence and high coercivity, and the content of rare earth is high. However, it has some disadvantages, that is, poor thermal stability. Once the temperature exceeds 150 ℃, it will cause irreversible demagnetization.

In addition, the NdFeB magnet contains a large amount of iron and neodymium metal materials, and the surface is easy to oxidize. If the coating process is unqualified, the NdFeB magnet will be partially oxidized during use, causing demagnetization.

2. Demagnetization caused by motor design

If the design of the motor does not fully understand the working conditions of the motor and make the actual working point lower than the inflection point of the demagnetization curve, irreversible demagnetization will occur in the process of use.

3. Demagnetization caused by improper use

The harsh environment of the motor, especially in the case of high temperature or violent mechanical vibration, will demagnetize the magnet of the motor. In addition, when the motor is overloaded for a long time and the temperature is too high, irreversible demagnetization of the motor will be caused

II. Anti-corrosion matters of injection molded bonded neodymium iron boron magnets

The common surface treatment of NdFeB magnet includes nickel plating (nickel copper nickel), zinc plating, aluminum plating, electrophoresis, etc. Bonded NdFeB magnets generally use Perrin coating or electrophoresis.

At present, the maximum working temperature of bonded neodymium iron boron magnets is about 180 ℃. It is suitable for harsh environments, generally no more than 140 degrees Celsius.

NdFeB magnets are widely used in packaging, toys, gifts and crafts, fitness magnetrons, motors, micromotors, cameras, computers, clocks, acoustics, instruments and meters, motorcycles, household appliances, office automation, magnetic therapy and various fields of daily life.

The above is about the reason analysis of demagnetization of NdFeB magnet and the introduction of anti-corrosion matters. I hope it will be helpful to you.

Maglastic has a self-supporting factory and injection molding experiment center focusing on the production of bonded magnetic compounds. The factory covers an area of 10000 square meters, has 8 sets of relevant production equipment and a production capacity of 10000 tons / year. Injection molding experiment center can provide customers with injection molds and injection molding product samples, which can quickly promote the development of the project. Welcome to consult.

Other Functional Composite Materials In addition to bonded magnetic compounds, we can also cooperate with customers to develop customized functional composite materials, such as high-density compounds and metal bonded plastic. We are committed to providing customers with new user experience and different design inspiration.

CN

CN

Call us on:

Call us on:  Email Us:

Email Us:  1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou

1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou