Based on customer consultation, we noticed that most of them are inquiring about the bonded ferrite magnet. It can be seen that there is a lot of demand for this type of magnet. Today, we will talk about why most customers choose the bonded ferrite magnet and the advantages of it.

1. Why choose the bonded ferrite magnet?

First of all, the bonded ferrite magnet has a relatively low cost, and it can be made by plastic injection molding. It has a simple process, which is suitable for mass production. The bonded ferrite magnet can meet the performance requirements of many small motors and sensors. Therefore, it can be widely applied.

Secondly, the bonded ferrite magnet has good high-temperature resistance and can be tested at 180℃, while other magnets may have lower temperature-resistance performance. The bonded ferrite magnet is very suitable for In high-temperature operation, there is no significant irreversible loss of magnetic properties of bonded ferrite magnet at high temperatures.

In addition, another important reason is that the bonded ferrite magnet can well meet customer needs, and different specifications can be made according to customer requirements during production.

2. What are the advantages of the bonded ferrite magnet?

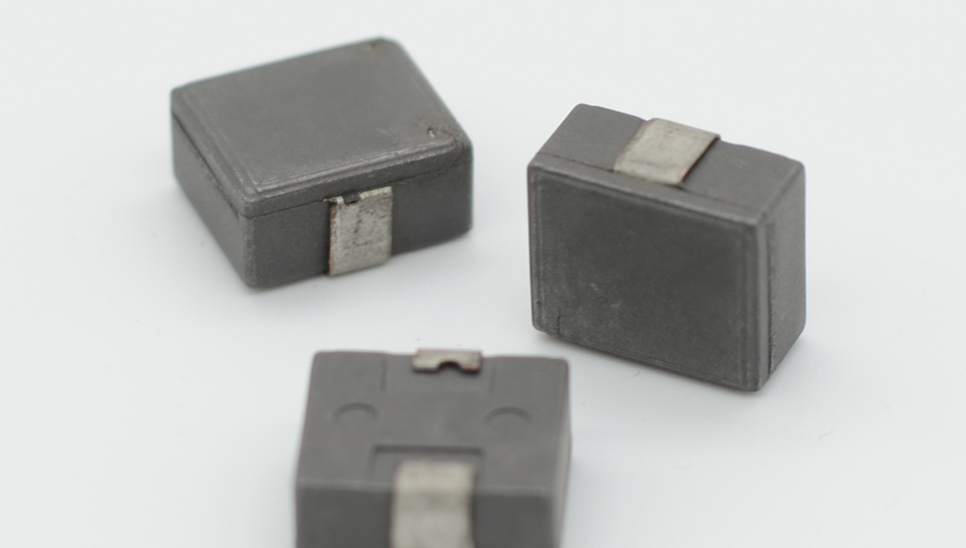

It is believed that you are not familiar with the bonded ferrite magnet, but you should be very familiar with the magnet. They are the same product. The polymer matrix and magnet powder are mixed during the production process, and a magnetic product can be made through the injection molding process. Therefore, what are its specific advantages compared with other magnets?

(1) Ferrite magnetic materials can be molded at one time, which can save costs for the company. Also, it will save a lot of manufacturing steps and costs during the process due to the one-time molding.

(2) In addition, it can be molded into various shapes during injection molding. Compared with other products, it has a more flexible production method so that it can meet different requirements of many customers and produce magnets suitable for different industries.

(3) It has an excellent performance and it contains a higher content of polymer binder due to the difference in production process and raw materials. Therefore, the magnet itself has strong corrosion resistance and usually does not need surface coating protection.

Other Functional Composite Materials In addition to bonded magnetic compounds, we can also cooperate with customers to develop customized functional composite materials, such as high-density compounds and metal bonded plastic. We are committed to providing customers with new user experience and different design inspiration.

CN

CN

Call us on:

Call us on:  Email Us:

Email Us:  1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou

1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou