1. Features of injection molded NdFeB magnets

Let's look at the features of injection molded NdFeB magnets.

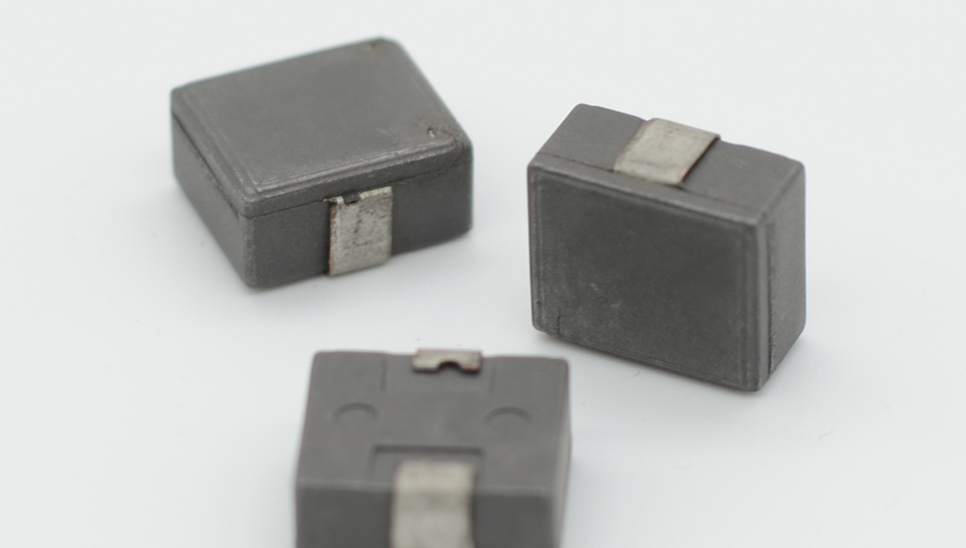

The NdFeB magnet is injection molded can be very complex shapes with high precision, usually with tolerance of +/- 0.005mm, which is suitable for high precision parts.

By inserting molding, the magnetic material can be molded directly into or onto other assembled parts without a secondary assembly process. The magnetic powder is neodymium iron boron (NdFeB), which can be isotropic or anisotropic. The polymer binder used is PA12, PPS or other resin matrix.

Our anisotropic injection molded NdFeB material has a maximum magnetic energy product (BH) max of 15 MGOe or more.

The NdFeB magnet thas is injection molded have excellent magnetic properties, but they are more expensive due to the use of rare earths. The cost can be reduced by mixing NdFeB and ferrite magnetic powder evenly and then granulating with resin matrix, such as the composite magnetic material of NdFeB and ferrite.

2. The advantages of choosing injection molding NdFeB magnets

Complex shape; good tolerance; no need of secondary assembly process of overmolding or insert molding; NdFeB, ferrite, SmFeN and other materials can be chosen; different powders can be mixed and then pelletized; (e.g., ferrite+NdFeB).

Injection molded NdFeB magnets are usually used in industrial, household appliances, automotive, medical fields, etc.

Other Functional Composite Materials In addition to bonded magnetic compounds, we can also cooperate with customers to develop customized functional composite materials, such as high-density compounds and metal bonded plastic. We are committed to providing customers with new user experience and different design inspiration.

CN

CN

Call us on:

Call us on:  Email Us:

Email Us:  1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou

1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou