Bonded ndfeb magnets are widely used in the automotive industry. Bonded ndfeb magnets are also used in many industries. For consumers, the performance and function of magnets are the main part. Today, we will introduce the matters of NdFeB magnets in testing and how long the magnetic properties will continue.

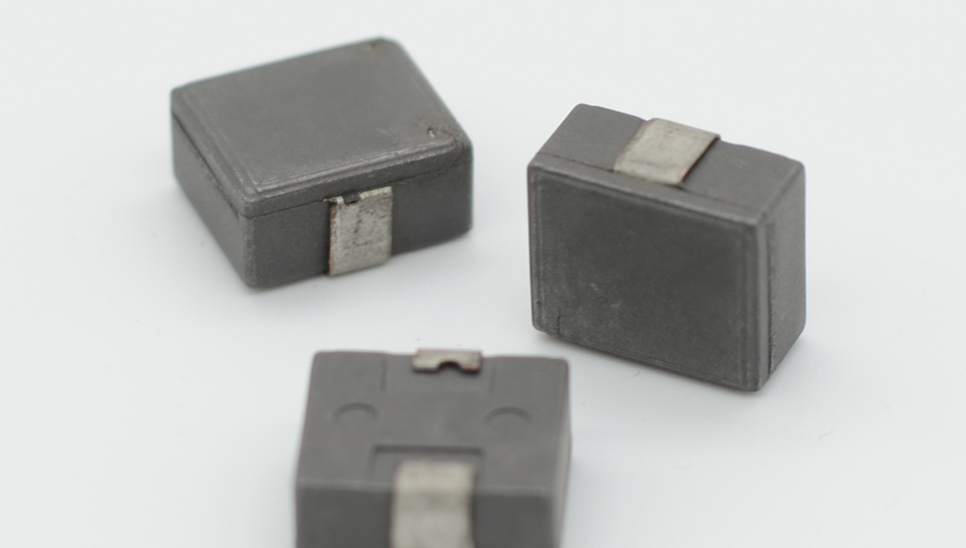

1. Matters of injection molding NdFe B magnet in testing

Micrometer, vernier caliper, Gauss meter, magnetic flux meter, film thickness meter and other measuring tools are usually used for the measurement of bonded ndfeb magnet. The film thickness meter is mainly used to measure the thickness of electrodeposited coating. It can effectively monitor the quality of plating solution and make flexible adjustment in the process of magnetic plating. Micrometer and vernier caliper measure the product tolerance and size, and the unit is mm.

The Gauss meter measures the magnetic force at a certain point on the magnet surface, and the unit is Gauss. Due to the different magnetic forces at each point on the surface of NdFeB magnet, the magnetic force at the edge is greater than that at the center, resulting in large measurement data error. The magnetic fluxmeter mainly measures the magnetic force on the side of NdFeB magnet, and the unit is Weber WB. Compared with Gauss meter, the magnetic flux measurement data is more objective and accurate.

Generally speaking, the manufacturer will choose the magnetic flux meter for testing. It is recommended that the user also use the magnetic flux meter during the inspection, so as to facilitate the measurement, unify the detection standard, and objectively, accurately and timely monitor the magnet quality.

2. How long can the magnetism of bonded neodymium NdFeB magnets last?

It is an object that can maintain its magnetism for a long time. Many people know the characteristics of a magnet. It can attract iron. Physically, magnets attract objects made of iron, nickel and cobalt. NdFeB magnets have many other uses. They can affect charged particles and conductors. Magnets can convert electrical energy into mechanical energy and vice versa. It is widely used in motor, electronics, mechanical equipment and other fields.

There are two main factors affecting the magnetic properties of strong magnets: temperature and oxidation. When the temperature exceeds the higher working temperature range of the permanent magnet, the magnetism of the permanent magnet will be weakened or even disappear; When the electroplated layer is damaged, the interior will be oxidized and the magnetism of the permanent magnet will be weakened.

If not exposed to these conditions, the permanent magnet will still lose its magnetism, but this degradation is very slow, decreasing by one percentage point every ten years. Therefore, if the permanent magnet is used correctly, there is no need to worry about the demagnetization of NdFeB magnet.

Other Functional Composite Materials In addition to bonded magnetic compounds, we can also cooperate with customers to develop customized functional composite materials, such as high-density compounds and metal bonded plastic. We are committed to providing customers with new user experience and different design inspiration.

CN

CN

Call us on:

Call us on:  Email Us:

Email Us:  1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou

1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou