To meet the requirements of electric and intelligent vehicles, we focus on providing lightweight, low energy consumption, reliable and safe solutions. Our different kind of magnetic material can be used for motors, sensors, electromagnetic shielding, etc.

The cooling water pump in the automotive thermal management system: With the promotion use of electric vehicles, the requirements for automotive thermal management are becoming higher and higher. An electronic water pump or the oil pump is a critical component in the system. The rotor made of a bonded magnetic compound has huge advantages in a lightweight and quality controllability. At present, bonded magnetic compounds like ferrite/PPS and NdFeB/PPS are both applied to pump rotors. No matter inner or outer rotors, both can be made of the bonded magnetic compounds. The blade and the rotor can be made by injection molding as a whole. Or you can just make the rotor part by injection molding, the blade can be made of other materials by secondary injection. Because of the controllable dimension of the injection magnet, it has advantages in dynamic balance. Besides that, our compound can withstand the high and low-temperature impact of -40 degrees to 150 degrees without cracking or other problems.

We are committed to the targeted research and development of a bonded magnetic compound, combining mold design and injection molding process optimization, and contributing to energy conservation.

2.

Sensor ring of automotive: From the initial vehicle speed sensor to intelligent driving, the application of a magnetic sensor ring is becoming more and more popular. At present, rubber magnet is used as raw materials for some magnetic sensors, but the mechanical properties of rubber make it unsuitable as an exposed component (it will be deformed easily by the impact from stone, and the performance will be an influence in high and low temperature). In addition, comparing to injection magnets, the magnetic properties of rubber magnets are lower ((BH) max≤1.4MGOe). And the longer sensing distance requires higher magnetic field strength of the surface. A bonded magnetic compound like ferrite with PA6 or PA12 binder can meet these requirements. The injection sensor ring that made by insert molding with the metal ring has the advantage of strength, toughness, and anti-collision, which enables the magnetic ring to be directly installed on the wheel hub. In addition, the surface magnetic field strength of the injection magnet is higher than the magnetic rubber, which enlarges the space between the induction probe and the magnetic ring.

3.

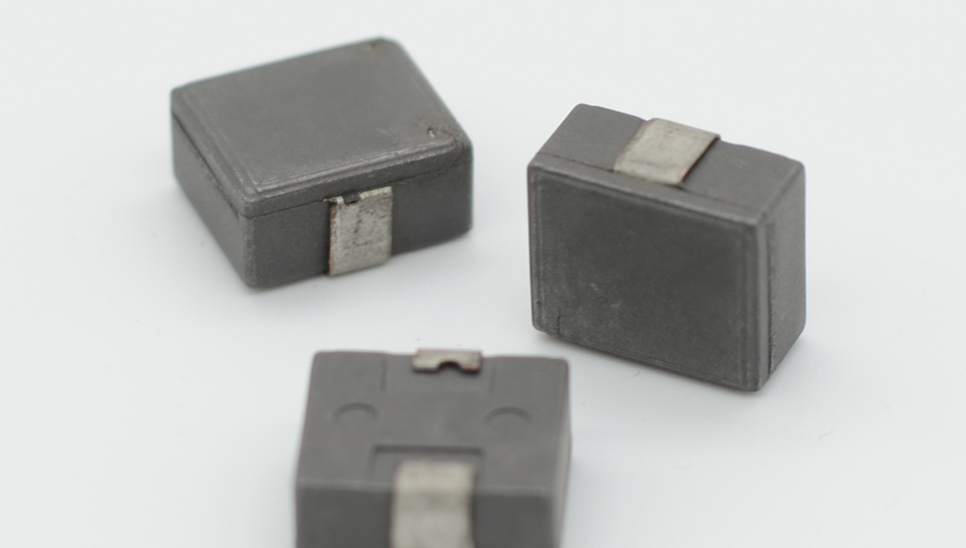

The induction magnetic ring for the automobile is applied in automobile sunroof, wiper, seat, window, etc. It is divided into separate injection-molded magnetic rings and magnetic rings with metal inserts. Due to the excellent mechanical properties and dimensional consistency of the injection magnet, the magnetic ring can be directly assembled on the shaft of the motor without cracking or falling off in use. Comparing to ferrite/PA6, it is much more recommended to use ferrite/PA12. Ferrite/PA 12 series has a lower absorption rate, which makes better dimensional stability to meet different needs in different environments. The material we developed has better mechanical properties and processing fluidity, which is not easy to be achieved in sintered magnets or other magnets. Injection magnets offer a better solution for the lightweight and comfort of the automotive.

4.

Automotive headlight steering motors: Because of the diversification of the structure design, an injection magnet provides a good solution for the production of a semi-arc rotor, reduces the amount of material without sacrificing other desirable traits, which is beneficial to the lightweight of the car. The recommended material is NdFeB /PPS series. It can be used at 200 degrees, which is applicable to the car lights. Our compound has greatly improved the problem of demagnetization at high temperatures. The good processing fluidity of the material also makes it easy to make small and special-shaped rotors by injection. At the same time, corrosion resistance of injection-molded NdFeB magnet is better than the ones that made by die pressing or sintering, as the plastic coating on the powder can avoid intergranular corrosion.

Other Functional Composite Materials In addition to bonded magnetic compounds, we can also cooperate with customers to develop customized functional composite materials, such as high-density compounds and metal bonded plastic. We are committed to providing customers with new user experience and different design inspiration.

CN

CN

Call us on:

Call us on:  Email Us:

Email Us:  1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou

1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou