According to the difficulty of demagnetization after magnetization, magnetic materials can be divided into soft magnetic materials and hard magnetic materials. Substances that are easy to demagnetize after magnetization are called soft magnetic materials, and those that are not easy to demagnetize are called hard magnetic materials. The following is an analysis of the development trend of the magnetic material industry.

As the country currently advocates energy conservation, environmental protection, and green development, as a clean energy, magnetic materials, especially injection molded magnetic materials, are becoming more and more widely used in emerging fields such as energy conservation and environmental protection, new energy, electric vehicles, smart cities, and smart earth. It has even begun to be used in military and defense fields such as robots, unmanned aerial vehicles, aerospace, satellite remote sensing.

Especially for the low-cost, resource-rich injection-molded ferrite permanent magnet materials, the overall market demand is growing at a rapid rate of 25% to 35% per year. In addition, the development of magnetic materials, as one of the key industries of the country, has been strongly supported by the national industrial policy.

At present, China and Japan have become the main production centers of NdFeB permanent magnet materials, and the total output accounts for more than 95% of the world. However, the United States, Europe and other developed countries and regions have gradually adjusted the industrial layout of rare earth permanent magnet materials for cost and profit considerations, and shifted the production of magnets, especially permanent magnet alloys, to China, the main source of rare earth materials.

From the perspective of industrial development and downstream market cycles, it is estimated that in the next five years, the downstream market of neodymium iron boron will complete the shift from traditional fields to emerging fields while the total amount is growing rapidly. As an emerging field in the field of new energy vehicles and robots, both sintered and injection molded magnets have great development potential, and there are also certain technical barriers.

The overall demand for new energy vehicles will increase from 4% to 27%, the demand for robotics will increase from 6% to 16%, and the demand for consumer electronics will decline, and the proportion of consumer electronics will reduce to less than 10% from 20%. The demand for injection molded magnetic products for new energy vehicles is gradually increasing, which will bring about the further development of injection molded magnets.

Emerging application areas will become the main driving force to promote the future demand for injection molding or sintering NdFeB, and new energy vehicles will be an important link in the future generation of incremental demand for high-performance NdFeB. The distinctive feature of NdFeB products in the field of new energy vehicles is that they have relatively high requirements for product specifications and accuracy, and there is a long product certification period.

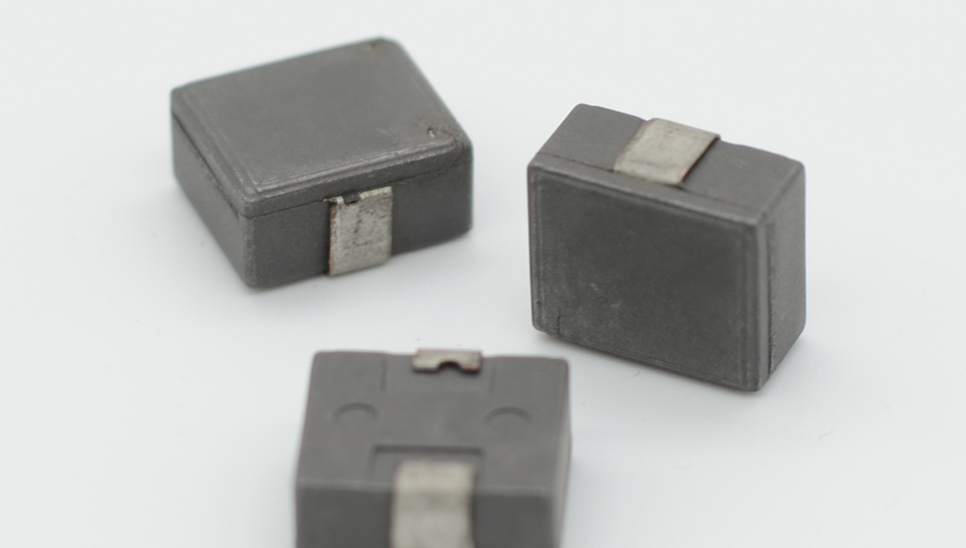

Other Functional Composite Materials In addition to bonded magnetic compounds, we can also cooperate with customers to develop customized functional composite materials, such as high-density compounds and metal bonded plastic. We are committed to providing customers with new user experience and different design inspiration.

CN

CN

Call us on:

Call us on:  Email Us:

Email Us:  1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou

1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou