In industries such as cosmetics, smart wear, toys, and other industries, we can provide innovative application possibilities and improve the user experience for your future products.

1.

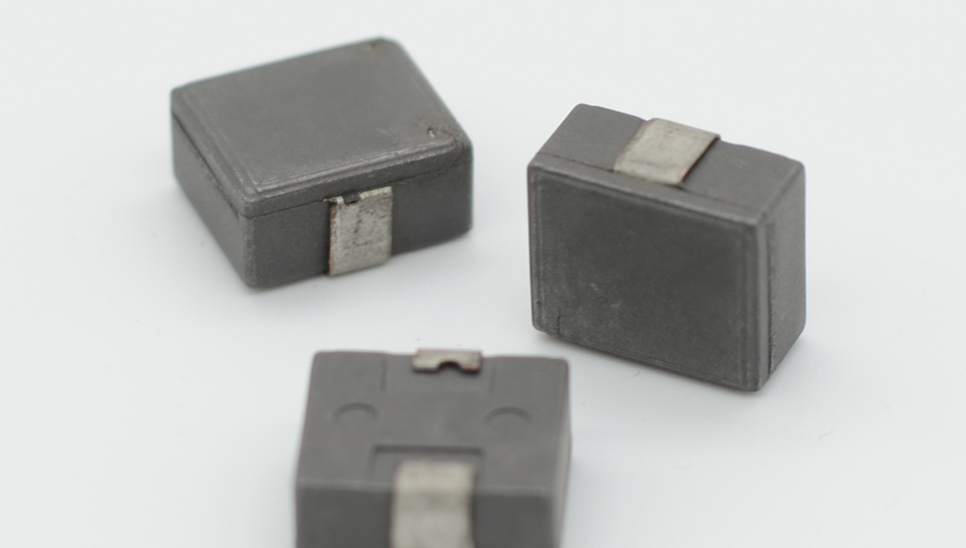

Generally, the traditional way for connecting two parts is through threads or mechanical snaps, like the lipstick tube and the concentrator of the hairdryer. Magnetic products changed this way. In the application of lipstick tube, we select the compound of NdFeB/PA12 or SmFeN/PA12 to make the ring in lipstick cap by injection, which has the advantage of high dimension precision and easy installation. Soft Magnetic Bonded Compounds is used to make the lipstick tube that can match to the magnetic ring in the lipstick cap to achieve the magnetic attraction effect. In the application of a hairdryer, the magnetic ring is molded in the concentrator of the hairdryer(insert molding). Different from the traditional magnetic ring, the shape of the injection magnetic ring on the concentrator is with conicity, and the orientation changes from axial two poles to single-sided multi-poles, which can achieve a much stronger magnetic force. In order to avoid the issue of demagnetization caused by the high temperature of the concentrator during the use of the hairdryer, we have optimized the material. We focus on developing more new applications for injection magnets to make our life easier.

2.

The rotor of the brushless DC motor on the electric curtain: It is very difficult to make a slim shape motor rotor with 90mm height and axial eight poles by sintered magnets. Injection magnet can avoid the oversized problem and also offer enough torsion from the motor. The recommended compound is ferrite/PA12 series, whose surface magnetic field can reach to 1700Gs. It is cost-effective to make the rotor by insert molding with a bonded ferrite compound. We are a company with abundant experiences in mold design and compound property. And with those experiences, we know the advantages of injection magnets in making the slim shape motor, and it will play an important role in the area of home automation.

3.

Induction ring for temperature or light brightness adjustment. It is generally used in coffee tumblers, baby bottles for temperature adjustment. And it is also used to adjust the brightness of the lights. These kinds of magnets generally have more than 20 poles, which can achieve more accurate adjustment. The wall thickness of the magnet is required within 2 mm so that the whole size of the knob and the lid can be controlled. The recommended compound to make this induction ring is ferrite/PA12 and NdFeB/PPS. PA12 series product is suitable to use in the environment temperature under 120℃,when PPS series product can be used in the higher environment temperature. We have rich experiences in improving the fluidity and mechanical toughness of the material to avoid the issues caused by the thin wall of the magnet.

4.

Induction rings can be used in electric bicycles for speed measure or induction. The gear or other parts can be molded by injection molding subsequently. The recommended compound is the PA6/PA12 ferrite series. And it is also recommended to use rare earth series compound if there's a higher requirement on the magnetic property. By injection molding, the induction ring can be shaped in a much more flexible structure. Injection magnets provide reliability for intelligent control of machinery and driving the safety of electric bicycles. We are willing to recommend a suitable grade according to the customer's requirements.

Other Functional Composite Materials In addition to bonded magnetic compounds, we can also cooperate with customers to develop customized functional composite materials, such as high-density compounds and metal bonded plastic. We are committed to providing customers with new user experience and different design inspiration.

CN

CN

Call us on:

Call us on:  Email Us:

Email Us:  1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou

1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou