Injection molded magnets are also a kind of bonded magnets, so what is an injection molded magnet?

1. What is the composition of injection molded magnets?

Injection molding is a molding method of injection and molding. After the thermoplastic resin and magnetic powder are mixed and granulated through the extruder, pressure is applied to the melted polymer solution through the plunger or screw of the injection machine, and the high-temperature solution is injected into the pre-closed through the nozzle and the runner system of the mold. In the low-temperature mold cavity, the final shape is cooled and the mold is opened to obtain a product with a certain geometric shape and precision.

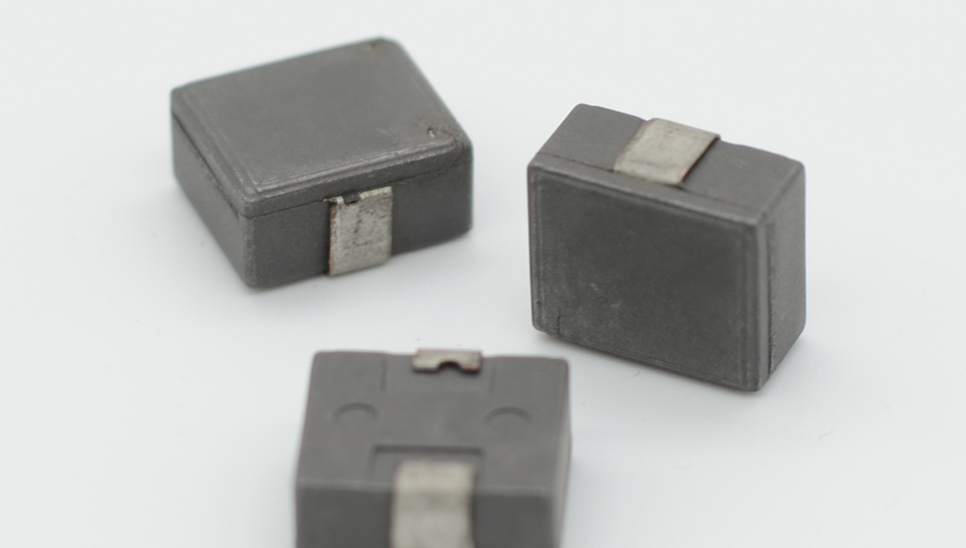

Injection molded magnets are composed of polymer resin and magnetic powder. It is a new type of composite magnetic material. It has a large degree of freedom in shape design, high dimensional accuracy, and performance can be adjusted as required. It can also be integrated with shafts, gears and other accessories, saving procedures and reducing costs. Injection molded magnets have high mechanical strength, complex shapes, and multi-pole magnetization. They are important basic materials in the field of modern science and technology.

2. The characteristics and applications of injection molded magnets

Injection molded magnets have a variety of substrates to choose from, such as nylon, polyphenylene sulfide, elastomeric plastics and other resins, which can be mixed with ferrite, neodymium iron boron, and samarium iron nitrogen and other magnetic powders. Magnets produced by injection molding technology have different advantages compared to other permanent magnet process methods.

The polymer binder content in the injection molded magnet is relatively high, so the magnet itself has better corrosion resistance. Generally speaking, there is no need for protection such as surface coating, and the precise size of the injection molded product can be controlled better.

Injection molded magnets are mainly used in some automation equipment, such as DC motor rotors, inverter air conditioner rotors, stepper motor rotors, cooling fan impeller rotors, water pump motor rotors, mechanical buzzers, micro speakers and other motor plastic magnetic rotors.

Other Functional Composite Materials In addition to bonded magnetic compounds, we can also cooperate with customers to develop customized functional composite materials, such as high-density compounds and metal bonded plastic. We are committed to providing customers with new user experience and different design inspiration.

CN

CN

Call us on:

Call us on:  Email Us:

Email Us:  1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou

1F, Building 3, NO.77 Gaoxin 13 road, Xiaoshan district, Hangzhou